High Torque Wrenches

(Sq Drive)

NSW 02 4966 1007 ~ QLD 0431 700 198 ~ WA 0418 802 973

Torsion X square drive hydraulic torque wrenches. Classic American quality & reliability. Supported by Torque Tools Direct in Australia, parts, technical knowledge & warranty. Compatible with other major brands. Full connectivity of Sq Drives, reaction arms, alco 21" alco arms, couplers, pumps & hoses.

The Sq Drive tools are designed for use with impact sockets, meaning multiple size sockets can be interchanged. The tools can be used as an accurate torque up tool, or a powerful loosening tool. These tools still remain the most versatile, genuine, tough torque tool option. Tested and proven over 20 years.

Point of difference -

These tools have fully adjustable reaction arms. Some brands only offer fixed arms locked in the downward position. Adjustability means deep sockets and uneven surfaces are easily overcome.

Regarding repairs calibration & service work, its all done locally meaning fast turnarounds. We also allow other suppliers to access spare parts & repair. You can tell when you have found the right tool.

|

|

|

|

|

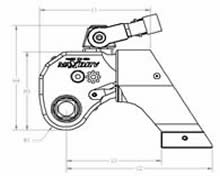

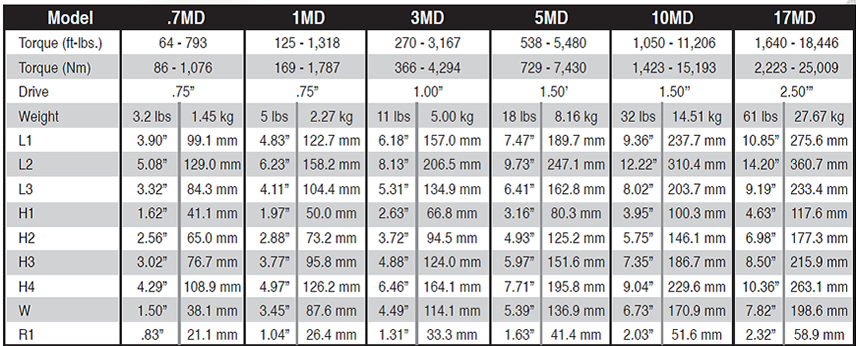

Square Drive Tools | ||||||||

| Part

No |

Model | Sq Drive |

Torque Ft Lbs |

Torque NM |

Adjustable Reaction Arm | HP Relief |

Accuracy + or - |

Weight | |

| 91062 | SQ-1 | 3/4" | 134 - 1344 | 183 - 1837 | Yes | Yes | 3% | 2.5 | |

| 91064 | SQ-3 | 1" | 300 - 3170 | 451 - 4512 | Yes | Yes | 3% | 5 | |

| 91066 | SQ-5 | 1-1/2" | 547 - 5470 | 752 - 7528 | Yes | Yes | 3% | 8 | |

| 91068 | SQ-8 | 1-1/2" | 783 - 7831 | 1078 - 10,780 | Yes | Yes | 3% | 11 | |

| 91070 | SQ-10 | 1-1/2" | 1130 - 11,200 | 1551 - 15,516 | Yes | Yes | 3% | 15 | |

| 91072 | SQ-17 | 2-1/2" | 1,700 - 18,450 | 2300 - 25,000 | Yes | Yes | 3% | 26 | |

| 91074 | SQ-25 | 2-1/2" | 2523 - 25,226 | 3472 - 34,725 | Yes | Yes | 3% | 35 | |

| 91076 | SQ-35 | 2-1/2" | 3535 - 35,354 | 4866 - 48,666 | Yes | Yes | 3% | 50 | |

| 91078 | SQ-50 | 2-1/2" | 5230 - 52,300 | 7200 - 72,000 | Yes | Yes | 3% | 87 | |

| Specifications | |||||||||

|

|

FULLY ADJUSABLE REACTION ARM: The arm can be positioned to engage slopping or curved surfaces or deep sockets. This is a critically important feature. Most brands of nut runners and Hyd wrenches are not adjustable. Fixed arms result in limited tool usability. 360 DEGREE Hyd SWIVLE: The hoses can be rotated away from obstructions - Safer PRESSURE RELEIF: The swivel has an inbuilt pressure relief to avoid pressure intensification. - Safer REACTION PAWL: Retains the load so the tool can ratchet again without the need to have hands on the tool. - Safer / Better MADE IN THE USA: High pressure, high load tooling manufactured in the USA to ISO standards and still price competitive - Quality matters. |

|||||||

|

|||||||||

| Accessories - ALCO Reaction Arms | |||||

| PICTURE | PART No | TOOL MODEL | LENGTH | WEIGHT | Alco Reaction Arms increase reaction options when the standard arm is unable to engage a reaction point. The Alco arms or "baseball bats" allow the operator to locate an alterative push point, or reaction point. This may be required if no near by options are available. The arm clips onto the rear of the wrench after removing the standard reaction arm. Change over is simple, and only takes a few seconds. |

|

90655 | SQ-1 | 21" | ||

| 90657 | SQ-3 | 21" | |||

| 90658 | SQ-5 | 21" | |||

| 90660 | SQ-8 | 21" | |||

| 90662 | SQ-10 | 21" | |||

| Accessories - DEEP Reaction Arms | |

|

DEEP REACTION ARMS - Deep Reaction arms offer solutions by extending the reaction for deep sockets. This also allows better access for clearing webbing or other frame work near by. |

| Hydraulic Wrench Pumps | |

HYDRAULIC WRENCH PUMPS ~ ELECTRIC |

|

HYDRAULIC WRENCH PUMPS ~ AIR Power Source: AIR 35-50 cfm @ 90 psi |

|

|

Hydraulic Torque Wrench Hose Set - Twin Line ID: 1/4" |

| In Field Applications | |

|

Oil & Gas - Pipe flanges - Water Supply, Refineries, Off Shore. Square Drive tools still remain a popular option for flanges. The main benefit being versatility. Sockets size can be inter-changed in seconds allowing for a wider range of tool usage. This also helps with tight budgets due to low cost of sockets. Highest power to weight ratio of all Sq Drv torque tool options For Pipe flanges these tools still remain the smallest , lightest, most powerfully option. Elbows, junctions, Tee's , small pcd centers. Pipe flanges have tight access. Its important you purchase the smallest torque tool option to avoid wasting time and money. See Hex Cassette tools for even better access options. Major refinery shutdowns still use these tools These tools remain the best option for access to elbows. junctions, Tee's and pcd centers. Square Drive tools offer 1% torque accuracy repeatability and offer full power in reverse for undoing tight bolts or studs. NOTE: Using sockets may create limitations for long studs, or tight overhead clearances please view the Hex Cassette Wrenches. These tools are a fully dedicated for Pipe flanges, shutdowns, refineries & larger requirements. |

|

Hitachi Workshop - Video |

|

WASHERIES - BRADFORD ROTARY BREAKERS Used mostly by the coal processing industry. These units break up over size coal. Inside the Bradfords is a rotating drum made up from steel segments plates. Holes in the plates segments have a cheese grater effect as material passes through the drum. These segments are normally bolted together via an eye beam type channels. The bolts are usually 1-1/8 with a 46mm a/f nut. Torque is around 1200 Ft Lbs. During maintenance the segments are replaced due to wear. By using the 'SQ-3' they are have seen a 95% improvement in bolts remaining tight. This is simply the result of applying the correct torque.

The 3 model is basically a hands free operation and delivers torque accuracy to with in 3% PROCESSING PLANTS CPP: Hydraulic Torque Wrenches play a large part of this industry. We have sold Hydraulic Torque Wrenches for applications like Jaw Crushers, Sizers, Cyclone feeders, Cone Crushers Bradford Breakers, Jacques Wear Plates and Frame Bolts, Crushing Coal Prep Plants ccp. Our tools apply accurate torque to ensure correct bolt load is applied in a safer way. Processing plant experiences constant and server vibration. Bolted joints need to be correctly torqued to ensure reliability. |

|

|

MINING EQUIPMENT - DOZER D10 D11 375 475 - We offer several torque tool models for dozer bolting. These include: Track master link bolts, Grouser Plate bolts, Sprocket bolts, Final Drive , Load Rollers, Frame and housing bolts, hub & front struts. Caterpillar Hydraulic Torque wrench for Dozer blade bolts, pedestal mounts are other classic applications for these torque tools. Komatsu Dozer torque wrenches needs to be tough and reliable. Avoid Improvising or swinging from unsafe tooling These tools can do the work for you. High Torque tools makes this job easy. |

|

MINING - The Hydraulic Torque Wrench provides +/- 3% torque accuracy with a 1% repeatability. Nothing competes with the Hydraulic Torque Wrench for size, Weight, Power to weight, torque accuracy and strength. We invite your company to join many others and enjoy the benefits of Hydraulic Tools. Our tools are used by the following Mining related companies in our region. |

|

|

HYDRAULIC TORQUE WRENCHES FOR MINING Above Ground - In the last 15 Years mining has embraced the benefits of Hydraulic tooling. Mining machinery uses high torques on high grade bolts often in tight access areas. The Hydraulic Wrench is the perfect solution. They are powerful, Small, Lightweight, Accurate , Tough and robust, and easy to use. Hydraulic Torque Wrenches have provided hundred of solutions for mining Industry. Hydraulic Wrenches has solved un-doing problems, access problems, and tool longevity issues in a harsh environments. Correct torque on heavy machinery is critical to ensure reliability. |

|

SPROCKET SEGMENT FINAL DRIVE BOLTS DOZERS: Torque requirements for these bolts are from 500 to 2,500 Ft lbs. Access is often tight requiring hydraulic tooling be used. Hydraulic torque tools are available for Hitachi, Liebherr, Caterpillar, Komatsu, Terex, P&H Volvo, Le Tourneau , DBT Voest Alpine, Bucyrus, DBT, Torque tools cover Dump Trucks, Excavators, Draglines,, Suspension frames, Engine mounts, Center pin bearings, Blade bolts wear plate bolts, Wheel nuts, Counter weight bolts, slu ring bolts, End covers. Mining Industries currently using Hydraulic Wrenches include Gold, Coal, Cooper, Diamond, Iron Ore, Uranium, Sand, Quarries etc.... Above and below ground. |

|

TRACKS MASTER LINK BOLTS CATERPILLAR Hydraulic Torque Wrenches make Master Link and Grozer Plate dozer Tracks easy work. Westrac, Hastings Deering, Komatsu all use Cat Multipliers or Torque wrenches for these bolts. Some manufactures use Torque Bolt rotation in degrees and others use torque. Hightorcs make Track bolts change outs easy. Eyre and Smith (Track Rebuild Specialists ) also recommend our tools during Dozer Track rebuilds. Track bolts experience all types of environments and loads. |

|

HEAVY INDUSTRY TORQUE TOOLS - Torque tools are designed to work in all areas of industry. Plastic Injection. Petrochemical, Mining, Rail, Quarries, Tower Cranes, Power Stations and more. These tools will improve safety, Time frames, and Bolt tension reliability.

|

|

CATAPELLER CYLINDERS - These bolts are often tight. These tools improve safety and provide correct torque on assembly. |

|

KOMATSU 475 - We find the 'SQ-5' tool suits 475 master link bolts best. This tool is 1-1/2" square drive with up to 5,400 Ft Lbs torque. We find the 'SQ-5' is ideal when un-doing when additional power is required. This tool only weighs 7.5kg with the reaction are fitted. This makes 475 track change outs faster, safer and with correct re torque. |

|

IMPACT SOCKETS |

|

|